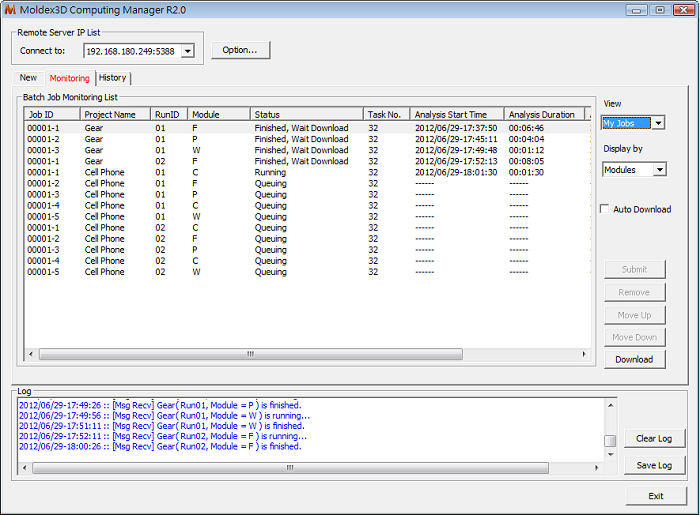

Heavy-duty computations happen when CAE engineers need to perform intensive design optimization iterations within the shortest time frame possible. Moreover, millions of 3D elements are usually involved in designing real industrial products. Moldex3D, however, can effectively help CAE engineers ease the burden of processing huge simulation models on a single computer by scheduling and assigning the jobs to multiple remote computing farms. Instead of constantly monitoring the analysis result without leaving personal workstations, users can enjoy the off-line convenience brought by Moldex3D remote computing features. With Moldex3D Remote Computing Manager (see Fig. 1), users will run simulation jobs in a data center and temporarily storing the project data. They can download the analysis results automatically after the computation is done and even receive email notifications of current status, keeping everything updated and efficient. Many world leading suppliers have already adopted Moldex3D for optimizing their runner and cavity designs. One of them adopted Moldex3D Computing Manager with 32-task cluster (8 computers, each with 4 CPU-cores) to perform simulations of huge complex models. Their case generally consists of 5 or 6 designs and each one has 3 to 4 process alterations, totally 15 to 24 jobs. With 12 million elements, it only takes 3.0 to 3.5 hours to finish a typical simulation iteration. YUDO, one of the world’s largest suppliers of hot runner systems, has leveraged on Moldex3D cluster technology for years. “We selected Moldex3D because it offers a better approach for more advanced and accurate engineering analysis technologies on the verification and optimization of hot runner system mold development, especially for true 3D analysis technology and private HPC cloud.†said Francis Yu, the chairman of YUDO. Moldex3D Computing Manager and cluster technology will give CAE engineers an edge in maintaining productivity and efficiency and which largely increases business agility. For more related information, please visit the Moldex3D product page. Aluminum Die Casting Auto Parts auto spare parts,precision casting company,Aluminum Die Casting Auto Parts Shenzhen Kangneng Fusheng Die Casting Products Co., Ltd. , https://www.knfsdiecasting.com Fig. 1  Moldex3D Computing Manager

Fig. 1 Â Moldex3D Computing Manager